All Categories

View All >-

Thermal Speed Ratings - Grease TIMKEN A-5224-WS A5200 Metric Cylindrical Roller Radial BearingSee More>

Thermal Speed Ratings - Grease TIMKEN A-5224-WS A5200 Metric Cylindrical Roller Radial BearingSee More> -

Chamfer r1smin2 TIMKEN 390RY2103 Four-Row Cylindrical Roller Radial BearingsSee More>

Chamfer r1smin2 TIMKEN 390RY2103 Four-Row Cylindrical Roller Radial BearingsSee More> -

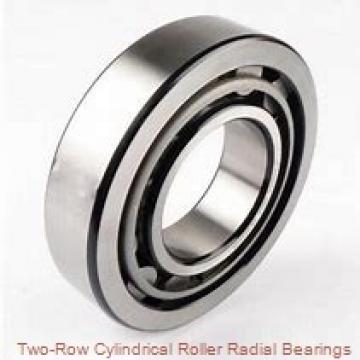

Dynamic Load Rating C11 TIMKEN NNU4976MAW33 Two-Row Cylindrical Roller Radial BearingsSee More>

Dynamic Load Rating C11 TIMKEN NNU4976MAW33 Two-Row Cylindrical Roller Radial BearingsSee More> -

50 mm x 130 mm x 31 mm Retainer NTN NU410G1C3 Single row Cylindrical roller bearingSee More>

50 mm x 130 mm x 31 mm Retainer NTN NU410G1C3 Single row Cylindrical roller bearingSee More>

Featured Products

Our Manufacturer with main products: A5200 Metric Cylindrical Roller Radial Bearing, Four-Row Cylindrical Roller Radial Bearings, Two-Row Cylindrical Roller Radial Bearings

-

80 mm x 140 mm x 33 mm Max operating temperature, Tmax NTN NUP2216EG1 Single row Cylindrical roller bearing

80 mm x 140 mm x 33 mm Max operating temperature, Tmax NTN NUP2216EG1 Single row Cylindrical roller bearing

-

50 mm x 130 mm x 31 mm Retainer NTN NU410G1C3 Single row Cylindrical roller bearing

50 mm x 130 mm x 31 mm Retainer NTN NU410G1C3 Single row Cylindrical roller bearing

-

80 mm x 200 mm x 48 mm ra max NTN NU416G1C4 Single row Cylindrical roller bearing

80 mm x 200 mm x 48 mm ra max NTN NU416G1C4 Single row Cylindrical roller bearing

-

25 mm x 52 mm x 18 mm Static load, C0 SNR NJ.2205.E.G15 Single row Cylindrical roller bearing

25 mm x 52 mm x 18 mm Static load, C0 SNR NJ.2205.E.G15 Single row Cylindrical roller bearing

-

75 mm x 190 mm x 45 mm Characteristic cage frequency, FTF NTN NJ415C4 Single row Cylindrical roller bearing

75 mm x 190 mm x 45 mm Characteristic cage frequency, FTF NTN NJ415C4 Single row Cylindrical roller bearing

-

35 mm x 80 mm x 21 mm Da max NTN N307ET2XC2 Single row Cylindrical roller bearing

35 mm x 80 mm x 21 mm Da max NTN N307ET2XC2 Single row Cylindrical roller bearing

-

30 mm x 62 mm x 20 mm Product Group - BDI NTN NUP2206EX2T2XU Single row Cylindrical roller bearing

30 mm x 62 mm x 20 mm Product Group - BDI NTN NUP2206EX2T2XU Single row Cylindrical roller bearing

-

60 mm x 130 mm x 31 mm BDI Inventory NTN NJ312ET2C3 Single row Cylindrical roller bearing

60 mm x 130 mm x 31 mm BDI Inventory NTN NJ312ET2C3 Single row Cylindrical roller bearing

-

50 mm x 110 mm x 27 mm D NTN NUP310NRU Single row Cylindrical roller bearing

50 mm x 110 mm x 27 mm D NTN NUP310NRU Single row Cylindrical roller bearing

-

25 mm x 62 mm x 17 mm Da max NTN NU305ET2XC3 Single row Cylindrical roller bearing

25 mm x 62 mm x 17 mm Da max NTN NU305ET2XC3 Single row Cylindrical roller bearing

-

30 mm x 72 mm x 27 mm Brand NTN NU2306EG1C3 Single row Cylindrical roller bearing

30 mm x 72 mm x 27 mm Brand NTN NU2306EG1C3 Single row Cylindrical roller bearing

-

120 mm x 215 mm x 40 mm d1 NTN NJ224EG1C3 Single row Cylindrical roller bearing

120 mm x 215 mm x 40 mm d1 NTN NJ224EG1C3 Single row Cylindrical roller bearing

-

35 mm x 80 mm x 21 mm Static load, C0 NTN NJ307EAT2X Single row Cylindrical roller bearing

35 mm x 80 mm x 21 mm Static load, C0 NTN NJ307EAT2X Single row Cylindrical roller bearing

-

75 mm x 160 mm x 37 mm EAN NTN NU315EG1C3 Single row Cylindrical roller bearing

75 mm x 160 mm x 37 mm EAN NTN NU315EG1C3 Single row Cylindrical roller bearing

-

60 mm x 130 mm x 46 mm Dynamic load, C NTN NU2312C3 Single row Cylindrical roller bearing

60 mm x 130 mm x 46 mm Dynamic load, C NTN NU2312C3 Single row Cylindrical roller bearing

-

75 mm x 115 mm x 20 mm rs min NTN NU1015G1 Single row Cylindrical roller bearing

75 mm x 115 mm x 20 mm rs min NTN NU1015G1 Single row Cylindrical roller bearing

-

100 mm x 215 mm x 47 mm F NTN N320C3 Single row Cylindrical roller bearing

100 mm x 215 mm x 47 mm F NTN N320C3 Single row Cylindrical roller bearing

-

B ZKL NU319EM Single row Cylindrical roller bearing

B ZKL NU319EM Single row Cylindrical roller bearing

-

50 mm x 110 mm x 27 mm bearing material: NTN NJ310G1C3 Single row Cylindrical roller bearing

50 mm x 110 mm x 27 mm bearing material: NTN NJ310G1C3 Single row Cylindrical roller bearing

-

70 mm x 125 mm x 31 mm Nlim (oil) NTN NUP2214U Single row Cylindrical roller bearing

70 mm x 125 mm x 31 mm Nlim (oil) NTN NUP2214U Single row Cylindrical roller bearing

-

110 mm x 240 mm x 50 mm Min operating temperature, Tmin NTN NU322C4 Single row Cylindrical roller bearing

110 mm x 240 mm x 50 mm Min operating temperature, Tmin NTN NU322C4 Single row Cylindrical roller bearing

-

90 mm x 160 mm x 30 mm Nref SNR N218EG15C3 Single row Cylindrical roller bearing

90 mm x 160 mm x 30 mm Nref SNR N218EG15C3 Single row Cylindrical roller bearing

-

B ZKL NU5209M Single row Cylindrical roller bearing

B ZKL NU5209M Single row Cylindrical roller bearing

-

50 mm x 110 mm x 40 mm Nlim (oil) NTN NU2310ET2C3 Single row Cylindrical roller bearing

50 mm x 110 mm x 40 mm Nlim (oil) NTN NU2310ET2C3 Single row Cylindrical roller bearing

-

95 mm x 200 mm x 45 mm Characteristic inner ring frequency, BPFI NTN N319EG1C3 Single row Cylindrical roller bearing

95 mm x 200 mm x 45 mm Characteristic inner ring frequency, BPFI NTN N319EG1C3 Single row Cylindrical roller bearing

-

100 mm x 180 mm x 34 mm Nlim (grease) NTN NU220G1C3 Single row Cylindrical roller bearing

100 mm x 180 mm x 34 mm Nlim (grease) NTN NU220G1C3 Single row Cylindrical roller bearing

-

45 mm x 100 mm x 36 mm Radial clearance class NTN NU2309EG1 Single row Cylindrical roller bearing

45 mm x 100 mm x 36 mm Radial clearance class NTN NU2309EG1 Single row Cylindrical roller bearing

-

240 mm x 440 mm x 72 mm Radial clearance class NTN NU248C3 Single row Cylindrical roller bearing

240 mm x 440 mm x 72 mm Radial clearance class NTN NU248C3 Single row Cylindrical roller bearing

-

70 mm x 150 mm x 35 mm r1s min NTN NUP314ET2XU Single row Cylindrical roller bearing

70 mm x 150 mm x 35 mm r1s min NTN NUP314ET2XU Single row Cylindrical roller bearing

-

80 mm x 170 mm x 58 mm D NTN NU2316C3 Single row Cylindrical roller bearing

80 mm x 170 mm x 58 mm D NTN NU2316C3 Single row Cylindrical roller bearing

-

55 mm x 120 mm x 43 mm Characteristic cage frequency, FTF NTN NU2311ET2C3 Single row Cylindrical roller bearing

55 mm x 120 mm x 43 mm Characteristic cage frequency, FTF NTN NU2311ET2C3 Single row Cylindrical roller bearing

-

30 mm x 72 mm x 19 mm da min NTN NJ306EG1C3 Single row Cylindrical roller bearing

30 mm x 72 mm x 19 mm da min NTN NJ306EG1C3 Single row Cylindrical roller bearing

-

b ZKL NU306 Single row Cylindrical roller bearing

b ZKL NU306 Single row Cylindrical roller bearing

-

40 mm x 80 mm x 23 mm Weight / Kilogram NTN NUP2208U Single row Cylindrical roller bearing

40 mm x 80 mm x 23 mm Weight / Kilogram NTN NUP2208U Single row Cylindrical roller bearing

-

85 mm x 150 mm x 36 mm F NTN NU2217G1C3 Single row Cylindrical roller bearing

85 mm x 150 mm x 36 mm F NTN NU2217G1C3 Single row Cylindrical roller bearing

-

45 mm x 85 mm x 19 mm rs min NTN NU209EAT2X Single row Cylindrical roller bearing

45 mm x 85 mm x 19 mm rs min NTN NU209EAT2X Single row Cylindrical roller bearing

-

65 mm x 120 mm x 31 mm rs min NTN NJ2213ET2 Single row Cylindrical roller bearing

65 mm x 120 mm x 31 mm rs min NTN NJ2213ET2 Single row Cylindrical roller bearing

-

50 mm x 90 mm x 23 mm Fatigue limit load, Cu NTN NU2210EG1C3 Single row Cylindrical roller bearing

50 mm x 90 mm x 23 mm Fatigue limit load, Cu NTN NU2210EG1C3 Single row Cylindrical roller bearing

-

30 mm x 72 mm x 19 mm da max NTN NJ306EG1 Single row Cylindrical roller bearing

30 mm x 72 mm x 19 mm da max NTN NJ306EG1 Single row Cylindrical roller bearing

-

rs (min) ZKL NU5208M Single row Cylindrical roller bearing

rs (min) ZKL NU5208M Single row Cylindrical roller bearing

A5200 Metric Cylindrical Roller Radial Bearing FAQS

QWhat's the cage of Cylindrical roller bearing ?

AThe main cage types are described in Components and materials. Additionally, information about standard cages, and possible cage options, for a particular bearing type is given in the relevant product section. If a bearing with a non-standard cage is required, check availability before ordering. Given the specific functional demands and quantity of bearings being manufactured, the material and manufacturing methods are chosen to provide the most reliable and cost-effective cage. Cages are mechanically stressed during bearing operation by frictional, impact, centrifugal and inertial forces. They can also be chemically influenced by certain organic solvents or coolants, lubricants, and lubricant additives. Therefore, the material type used for a cage has a significant influence on the suitability of a rolling bearing for a particular application.

QWhat about steel cage ?

ASteel cages can be used at operating temperatures up to 300 °C (570 °F). Sheet steel cages Stamped sheet steel cages are made of low carbon steel. These lightweight cages have relatively high strength and, for some bearing types, can be surface treated to further reduce friction and wear in critical conditions. Machined steel cages Machined steel cages are normally made of non-alloyed structural steel. To reduce friction and wear, some machined steel cages are surface treated.

QWhat is brass cage ?

ABrass cages can be used at operating temperatures up to 250 °C (480 °F). Sheet brass cages Stamped sheet brass cages are used for some small and medium-size bearings. In applications such as refrigeration compressors that use ammonia, machined brass or steel cages should be used.

QWhat is Polymer cages ?

APolyamide 66 Polyamide 66 (PA66) is the most commonly used material for injection moulded cages. This material, with or without glass fibres, is characterized by a favourable combination of strength and elasticity. The mechanical properties, such as strength and elasticity, of polymer materials are temperature dependent and subject to ageing. The factors that most influence the ageing process are temperature, time and the medium (lubricant) to which the polymer is exposed Polyamide 46 Glass fibre reinforced polyamide 46 (PA46) is the standard cage material for some small and medium-size CARB toroidal roller bearings. The permissible operating temperature is 15 °C (25 °F) higher than for glass fibre reinforced PA66

Hot Searches

- • Static Load Rating Co TIMKEN A-5230-WS A5200 Metric Cylindrical Roller Radial Bearing PDF

- • Thermal Speed Ratings - Grease TIMKEN A-5224-WS A5200 Metric Cylindrical Roller Radial Bearing PDF

- • Type TIMKEN A-5236-WS A5200 Metric Cylindrical Roller Radial Bearing PDF

- • Dimension S2 TIMKEN A-5222-WS A5200 Metric Cylindrical Roller Radial Bearing PDF

- • Bore d TIMKEN A-5238-WS A5200 Metric Cylindrical Roller Radial Bearing PDF

- • Thermal Speed Ratings - Oil TIMKEN A-5244-WM A5200 Metric Cylindrical Roller Radial Bearing PDF

- • Chamfer rsmin TIMKEN A-5232-WS A5200 Metric Cylindrical Roller Radial Bearing PDF

- • Thermal Speed Ratings - Grease TIMKEN A-5234-WS A5200 Metric Cylindrical Roller Radial Bearing PDF

- • Backing Housing Diameter Ds TIMKEN A-5226-WS A5200 Metric Cylindrical Roller Radial Bearing PDF

- • Thermal Speed Ratings - Oil TIMKEN A-5220-WS A5200 Metric Cylindrical Roller Radial Bearing PDF

- • Weight TIMKEN A-5228-WS A5200 Metric Cylindrical Roller Radial Bearing PDF

- • Dimension S2 TIMKEN A-5248-WM A5200 Metric Cylindrical Roller Radial Bearing PDF

- A5200 Metric Cylindrical Roller Radial Bearing

- Thermal Speed Ratings - Grease TIMKEN A-5224-WS A5200 Metric Cylindrical Roller Radial Bearing

- Static Load Rating Co TIMKEN A-5230-WS A5200 Metric Cylindrical Roller Radial Bearing

- Dimension S2 TIMKEN A-5222-WS A5200 Metric Cylindrical Roller Radial Bearing

- Four-Row Cylindrical Roller Radial Bearings

- Chamfer r1smin2 TIMKEN 390RY2103 Four-Row Cylindrical Roller Radial Bearings

- Lubrication Hole Diameter h TIMKEN 300RX1846 Four-Row Cylindrical Roller Radial Bearings

- O.D. D TIMKEN 705RX3131B Four-Row Cylindrical Roller Radial Bearings

- Two-Row Cylindrical Roller Radial Bearings

- Dynamic Load Rating C11 TIMKEN NNU4976MAW33 Two-Row Cylindrical Roller Radial Bearings

- Dimension S4 TIMKEN NNU4944MAW33 Two-Row Cylindrical Roller Radial Bearings

- Chamfer r1smin3 TIMKEN NNU49/900MAW33 Two-Row Cylindrical Roller Radial Bearings

- About Us

- Company Profile

- Contact Info

- Site Map

- Sitemaps